— All Kuboox pallets have the specific data sheet, by showing their load capacity values. The load capacity values are obtained from breaking and load tests carried out in accredited laboratories.

The load on a pallet can have several variables: size, weight, shape/distribution, operating temperature, etc. Choosing the right pallet to avoid sagging is important first of all for the safety of people and then for obvious issues related to damage resulting from an unwanted fall or movement of the load.

The European standard

EN ISO 8611-1 (August 2012 edition) specifies the specific test methods, available for the evaluation of new flat pallets for goods handling. The test methods are divided into groups for:

- nominal load tests

- maximum working load tests

- comparative durability tests

From these tests, carried out in approved laboratories, each manufacturer is required to issue an

estimate of the load capacity to which the pallet can be subjected. The estimated load capacity is a rough figure, useful in the early stages of pallet design, and is calculated using simulation software. Each new pallet placed on the market must be accompanied by a technical

data sheet showing the general characteristics, the intended use and the load capacity, which can be declared in:

- estimation of STATIC LOAD CAPACITY

- estimation of DYNAMIC LOAD CAPACITY

- estimation of RACK LOAD CAPACITY

ESTIMATION OF STATIC LOAD CAPACITY

Static load capacity is the capacity of a

new, stationary pallet, resting well on the floor and at a temperature of 25°C, to withstand a load without being damaged or causing damage to the goods it supports. It is always the highest capacity value (about twice as high as the dynamic one). The STATIC LOAD BEARING value should only be taken into account if it is used

to support goods which are stationary and resting on the floor or on a stable surface with a load capacity greater than that of the pallet itself.

ESTIMATION OF DYNAMIC LOAD CAPACITY

When using pallets on

transport equipment (pallet truck, forklift truck, road, ship, air), the dynamic load capacity must always be taken as a reference.

Dynamic load capacity means

the ability of a new pallet operating at a temperature of 25°C to handle goods without being damaged or injure the load being transported. The DYNAMIC load capacity is always the lowest value (about half of the static value).

ESTIMATION OF RACK LOAD CAPACITY

Pallets used in warehouses and for storage on shelves, may be subject to various load stresses. When using

pallets on shelves, another element that comes into consideration is their ability to resist

bending/shattering, as they do not normally rest on the entire floor base but only on the shelf's crossbars. This is why pallets designed for this use have

standard dimensions that are coordinated with the width of a shelf in order to rest securely.

In order to increase the load capacity of a pallet on a rack, it is possible to equip it with

reinforcing crossbars, which decrease its flexibility and increase its anti-breakage capacity.

FURTHER CONSIDERATIONS

The load capacity of a pallet is a rough indication, or an estimate that will help you choose the most suitable pallet for your purpose. It cannot be considered an absolute and certain dimension that can be completely relied upon.

Other factors such as the shape and distribution of the load, horizontal and vertical stresses (e.g. caused by a bumpy floor/road or sea/air transport), pallet conditions, humidity and operating temperature can significantly alter the pallet load references.

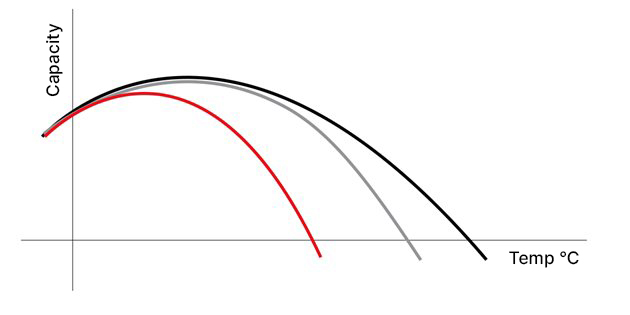

Decay of the load capacity of a generic pallet according to the operating temperature

— Static load capacity //

— Rack load capacity //

— Dynamic load capacity